Factors Influencing the Cost of Adding a Gas Line

The total expense for installing a new gas line is determined by a combination of factors. Understanding these can help you anticipate potential costs.

- Length and Route of the Pipe: Longer distances and complex routes requiring navigation around obstacles or through difficult terrain (e.g., concrete slabs, finished walls) will increase labor and material costs.

- Pipe Material: Common materials include black iron pipe and corrugated stainless steel tubing (CSST). CSST is often quicker to install but may have higher material costs per foot than black iron. The choice may also be dictated by local building codes.

- Accessibility: The ease with which plumbers can access the installation area (e.g., crawl spaces, basements, attics versus buried lines requiring trenching) significantly impacts labor time.

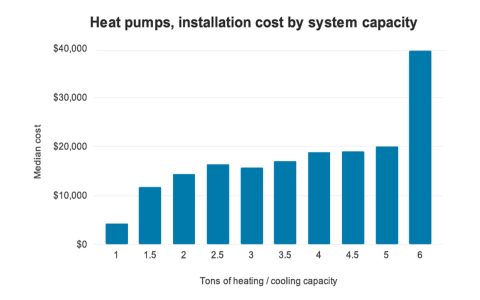

- Type and Number of Appliances: Connecting multiple appliances or high-demand appliances (like tankless water heaters or generators) might necessitate larger diameter pipes or even upgrades to your gas meter or main service line, adding to the cost.

- Permits and Inspections: Most jurisdictions require permits for gas line work. The cost of these permits and any subsequent inspections by local authorities will be part of the overall expense.

- Labor Rates: Licensed plumbers' hourly rates vary considerably by geographic location, the complexity of the job, and their experience.

- Trenching and Excavation: For outdoor gas lines (e.g., to a grill, pool heater, or generator), the cost of trenching, backfilling, and potential landscape restoration will be a major component.

- Pressure Testing and Safety Checks: All new gas lines must be meticulously pressure tested to ensure there are no leaks. This is a critical safety step and a standard part of the installation process.

Typical Cost Estimates

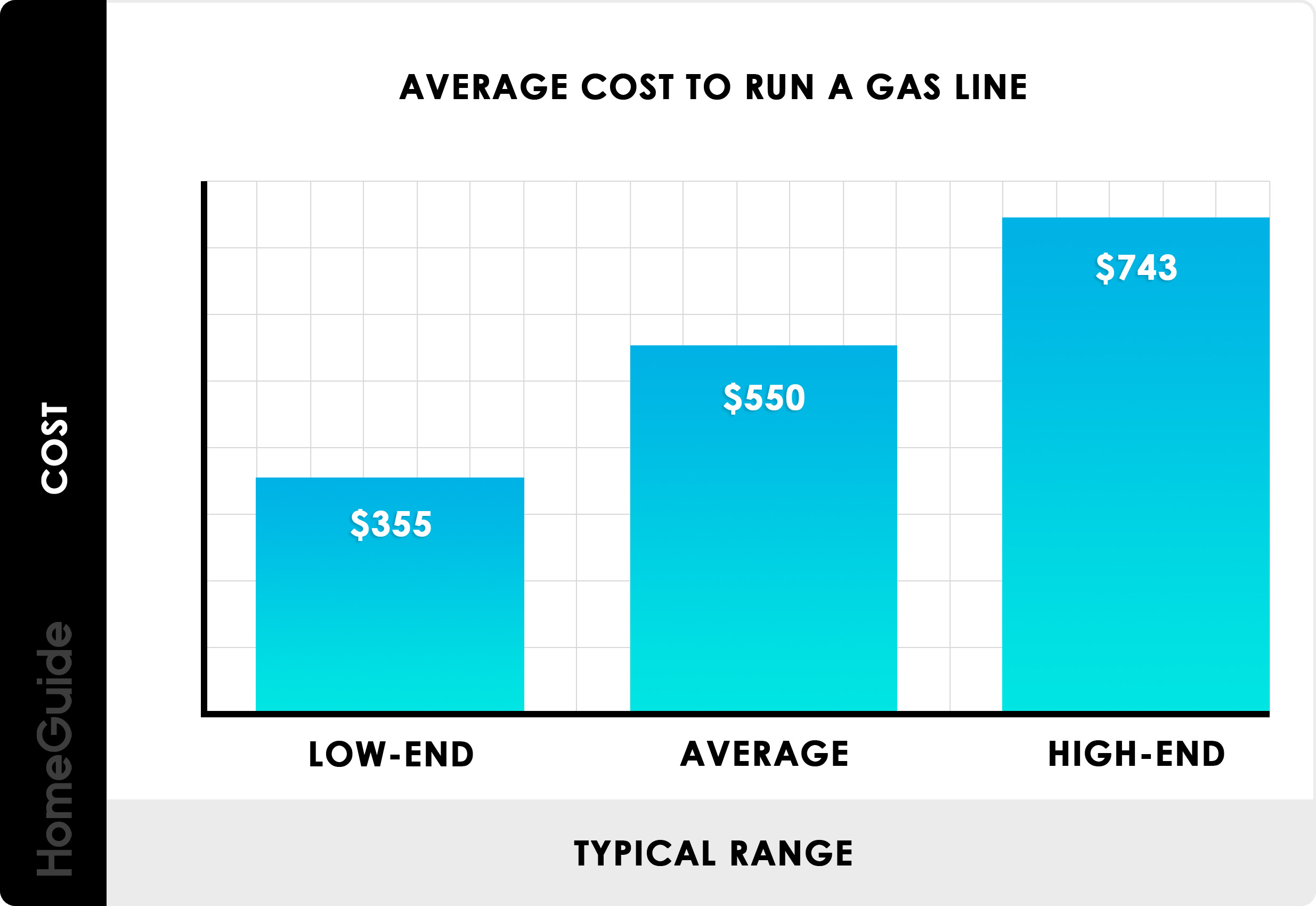

While costs vary significantly based on the factors above, here are some general ranges. It is crucial to obtain detailed quotes from qualified professionals for your specific project.

- Per Linear Foot: Expect costs to range from $15 to $30+ per linear foot for basic interior installations. This can increase substantially for exterior lines requiring trenching, complex interior runs, or larger diameter pipes.

- Simple Appliance Hook-up: Connecting a single appliance like a gas stove or clothes dryer where a gas stub-out is already nearby might cost between $200 and $500.

- New Line Installation: Installing a completely new line to an appliance such as an outdoor BBQ, fireplace, or a tankless water heater can range from $500 to $2,500+, highly dependent on distance, complexity, and local labor rates.

- Major Extensions or Upgrades: Projects requiring extensive new piping throughout a house, significant rerouting, or upgrades to the gas meter and service line from the utility company can exceed $5,000.

Note: These figures are broad estimates for planning purposes only. Material costs and labor rates fluctuate. Always secure itemized quotes.

Important Considerations When Adding a Gas Line

Beyond the direct financial outlay, several crucial aspects require attention when planning to add or extend a gas line.

- Safety and Professional Installation: Gas line installation is inherently dangerous if not performed correctly and is not a DIY project. Always hire a licensed, insured, and experienced plumbing contractor specializing in gas line work. They will be knowledgeable about current local codes, safety standards, and proper installation techniques.

- Permits and Inspections: Ensure your contractor obtains all necessary permits from your local municipality before work commences. After installation, a mandatory inspection by a city or county inspector is typically required to verify compliance and safety. Do not make final payment until the work passes inspection.

- Obtain Multiple, Detailed Quotes: Solicit at least three written quotes from reputable, licensed contractors. Compare the scope of work outlined, materials to be used (e.g., black iron pipe vs. CSST), warranties offered, timelines, and the contractor's credentials and references. Do not base your decision solely on the lowest price.

- Existing Gas System Capacity: Your current gas meter and service line must have adequate capacity to handle the increased load from any new gas appliances. Your contractor should assess this. If the system is undersized, an upgrade by your gas utility company may be necessary, which can incur additional costs and lead times.

- Material Choice and Code Compliance: Discuss material options with your contractor. While CSST can be more flexible and faster to install in some situations, black iron pipe is often considered more durable. The choice must comply with all local building and gas codes.