A hydroseeder is specialized machinery designed for hydroseeding, a planting process that involves spraying a slurry of seed, mulch, fertilizer, water, and often a tackifier onto prepared ground. This method facilitates rapid, uniform vegetation establishment across various terrains.

Core Components of a Hydroseeder

Effective hydroseeding relies on several key components integrated into the machine:

- Tank: A container, typically made of steel, stainless steel, or polyethylene, that holds the hydroseeding mixture. Capacities vary widely depending on the model and application scale.

- Agitation System: Crucial for maintaining a homogenous slurry and preventing the settling of materials. This can be achieved through mechanical paddles, recirculation jets, or a combination.

- Pump: A robust pump (e.g., centrifugal or positive displacement) is essential to draw the slurry from the tank and propel it through the hose and nozzle at sufficient pressure for even distribution.

- Power Source: Typically a gasoline or diesel engine, or an electric motor on smaller units, which powers the pump and agitation system.

- Hose and Nozzle: The hose delivers the slurry to the application area, while specialized nozzles allow the operator to control the spray pattern, width, and distance.

- Discharge System: Includes valves and controls that regulate the flow and application of the hydroseeding slurry.

The Hydroseeding Process

The process of applying hydroseed with a hydroseeder involves distinct steps:

- Site Preparation: The target area is graded, cleared of debris, and sometimes tilled to ensure optimal seed-to-soil contact. Soil tests may be conducted to determine necessary amendments.

- Slurry Mixing: The hydroseeder tank is filled with a measured amount of water. Seed, mulch (e.g., wood fiber, paper, or a blend), fertilizer, tackifying agents, and other additives like biostimulants or soil conditioners are then added. The agitation system thoroughly blends these components into a consistent slurry.

- Application: The operator directs the hose and nozzle to spray the slurry evenly over the prepared ground. The application rate is carefully managed to ensure complete coverage without oversaturation.

- Establishment: The applied mulch layer protects the seeds, conserves moisture, moderates soil temperature, and helps prevent erosion, creating an ideal microenvironment for germination and seedling growth.

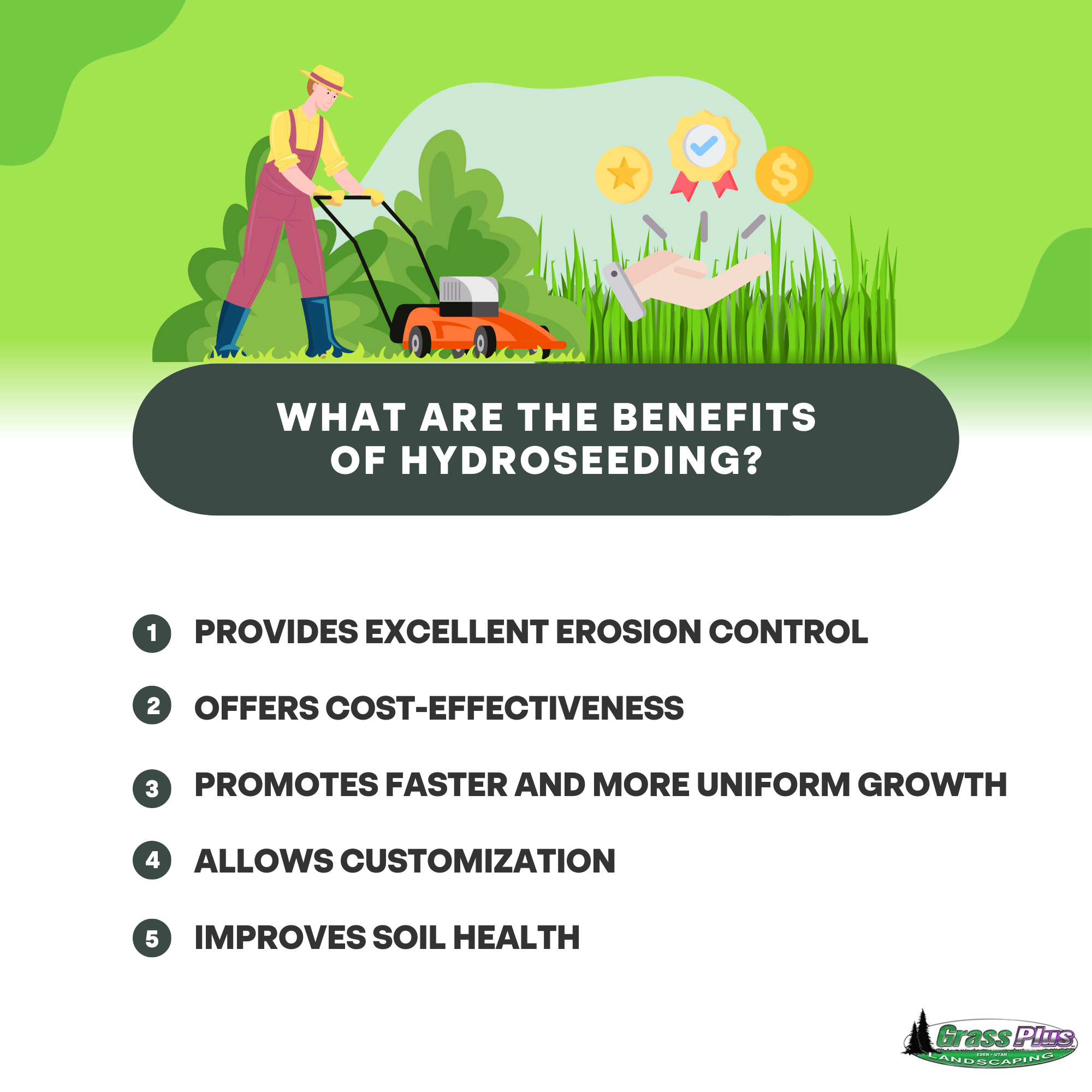

Advantages of Using Hydroseeders

Hydroseeding offers significant benefits over traditional seeding methods or sodding:

- Efficiency: Allows for rapid seeding of large or difficult-to-access areas.

- Erosion Control: The mulch and tackifiers bind soil particles, providing immediate erosion protection, especially on slopes.

- Uniform Coverage: Ensures even distribution of seeds, fertilizer, and mulch, leading to consistent vegetation.

- Enhanced Germination: The slurry creates a moist, nutrient-rich environment that promotes higher germination rates and faster establishment.

- Cost-Effectiveness: Generally less expensive than sodding for large areas and can be more successful than dry seeding in challenging conditions.

- Versatility: Suitable for various applications, including lawns, sports fields, roadside revegetation, and land reclamation projects.

Key Considerations for Hydroseeding Operations

When planning or executing hydroseeding projects, or selecting a hydroseeder, several factors are important:

- Project Scale: Influences the required tank capacity and power of the hydroseeder.

- Terrain and Accessibility: May dictate the type of hydroseeder (e.g., trailer-mounted, skid-mounted, truck-mounted) and hose length needed.

- Slurry Composition: The type and amount of mulch (especially heavier wood fiber mulches) will affect the required agitation and pump capabilities.

- Water Availability: A reliable water source is essential for mixing the slurry.

- Maintenance Requirements: Regular cleaning and maintenance of the tank, pump, and hoses are crucial for longevity and performance.

- Operator Skill: Proper calibration and application techniques are vital for achieving optimal results.